The applications of commercial storage are covered in detail on this page. In summary they are as follows:

| Application | |

| Increased on-site use of solar power / micro-generation | E.g. store solar power for use in the evenings. |

| Reduce peak demand chargers - 'buy cheap, use peak' | Avoid TRIAD charges, reduce DUOS charges. |

| Earn grid income | Capacity Market, Firm Frequency Regulation. |

| Overcome grid constraints | E.g. trickle charge battery, fast charge EV cars. Avoid peak demand constraints. |

| Commercial UPS battery backup (in a power cut) | E.g. for emergency lighting, essential power. |

| Off-grid | Anything is possible with a generator and micro-generation. |

| Reduce carbon footprint | Reduce line losses, alleviate need for further fossil fuel investment by balancing supply and demand, thus reducing peak demand. |

There are three main system components:

Most of the system cost is attributable to the battery.

Most of the functionality (ability to provide backup, peak charge avoidance, enablement of solar during a power cut) is attributable to the inverter / charger and the battery management system.

Key design considerations are as follows:

A system can either be assembled from individual components, combining for example a Samsung battery with an ABB converter (inverter / charger), or it can be purchased as a 'package' in which the battery and inverter / charger are packaged by the manufacturer, often into a single unit (e.g. Tesla Powerpack) or container (e.g. Sungrow-Samsung).

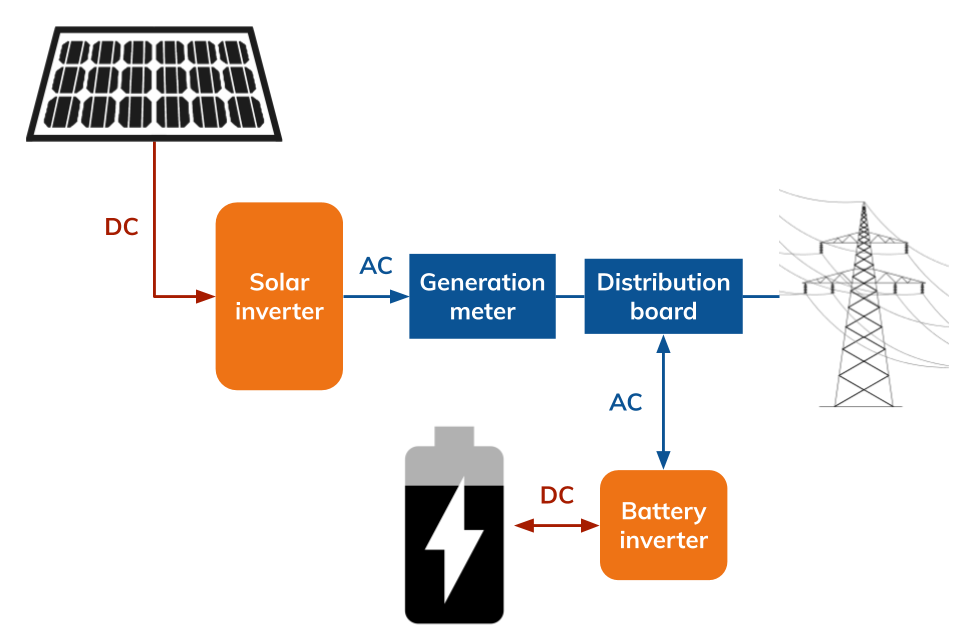

Most systems are 'AC-coupled' i.e. connected to the AC wiring, either at low voltage or at high voltage. The system may or may not include solar panels:

There are five key chemistries:

The application dictates the charge / discharge behaviour, generally making one particular chemistry more suitable and / or cost effective than the others. In general the lithium ion chemistries (NCM and LFP) are for faster charge and discharge applications (e.g. grid balancing FFR), whereas flow batteries and zinc based batteries are for slower charge and discharge applications (and tend to be cheaper).

The table sets out a comparison of NCM, LFP, flow batteries and zinc-air batteries:

| Lithium nickel (NCM) | Lithium ferro phosphate (LFP) | Zinc hybrid | Vanadium redox | |

| No of life cycles | ~ 5,000 life cycles at 80% depth of discharge. |

For Simpli-Phi:

|

5,000 life cycles at 100% depth of discharge. | 10,000 cycles at 100% depth of discharge. |

| Expected life at 250-300 life cycles per year | 15 - 17 years | 30 years | 15-17 years | 30 years |

| "End-of-life" capacity | Typically guaranteed to operate at 60-70% of original capacity after 5,000 life cycles. | Typically guaranteed to operate at 70% of original capacity after 10,000 lifecycles. | Depends on application. | Depends on application. |

| Temperature tolerance | Optimum operating range 15°C to 30°C (some can operate between -20°C and 50°C. Packaged systems typically have in built ventilation. | LFP does not require ventilation, cooling or thermal regulation (although inverters / switchgear need some ventilation and may require thermal regulation). | Operating temperature of 0°C to 45°C without HVAC, -30°C to 70°C with HVAC. | Operating temperature of -40°C to 50°C. |

| Safety | Very good with correct system choice. Suitable for residential or commercial use. Some hazard in the event of fire / thermal runaway, although good brands have multiple safety mechanisms in place. Invest in quality, and install and operate in accordance with manufacturer instructions. | Very good - safest most environmentally benign lithium ion chemistry available - no risk of thermal runaway or fire. | Non-flammable aqueous electrolyte has no flashpoint; non hazardous and non-corrosive when shipped. | The battery is emissions free, non-flammable, non-explosive and contains no heavy metals. |

| Very rough cost per MWh | USD 360-460 | USD 890 | USD 200 | TBC |

| Environmental / reputational | Child labour can be used to mine cobalt in the Congo – it is not clear whether Samsung is using cobalt from this source. | Non-toxic, and non-hazardous recyclable materials. | Non-hazardous. | After 25 years the vanadium electrolyte can be reused in a new system. |

| Brands | Samsung, Tesla, Tesvolt, LG Chem | Simpli-Phi, Sony | EOS | RedT, UET |

The main inverter charger manufacturers are as follows:

In addition there are 'packaged' systems in which the battery and inverter / charger are combined into one solution, usually containerised. Some of the key players are as follows:

Copyright © Spirit Energy 2024 · info@spiritenergy.co.uk · 0118 951 4490

Spirit House, 25 Albury Close, Reading, RG30 1BD

(Location formerly known as 44 Portman Road, Reading, RG30 1EA)

Spirit Energy is the trading name of Spirit Solar Ltd · UK Company Number 07138647

Although care is taken to ensure that the information on our website (www.spiritenergy.co.uk) and any guides, calculators or checklists provided by us, electronically or otherwise, are accurate and up-to-date, we cannot accept any responsibility for mistakes or omissions. We enter into no express or implied conditions, warranties, terms or representations regarding the quality, accuracy or completeness of the information. We exclude to the extent lawfully permitted all liability for loss or damage, whether direct, indirect or consequential arising out of your use of our website or any guides, calculators or checklists provided by us, or from any information or omission contained in our website or any guides, calculators or checklists provided by us.