The following selection criteria should be considered when choosing an inverter:

Each of these criteria is discussed in detail below. We have also produced a comparison table for various inverter brands.

We use a variety of solar power inverters, all of them market-leading. The domestic scale inverters are listed in the table below. Most of these manufacturers also offer much larger three phase inverters, allowing the configuration of large commercial systems, potentially with MegaWatts of power.

Overall, the highest quality standard inverters on the market are generally considered to be those made by SMA and Fronius, with SolarEdge inverters being used where there are varying levels of sunlight or shading across the array.

The best 'hybrid' and 'off-grid' inverters include those made by SMA and Victron. These allow the connection of a battery as well as panels. In this day and age, where battery storage is becoming more and more common, installing a hybrid inverter makes a lot of sense, even if you don't intend to connect a battery straight away.

Sitting below these in both price point and quality are Solis, Solax, Growatt and, for hybrid solar / battery systems, GivEnergy: decent but not best quality at an affordable price.

|

Manufacturer (Origin) |

Range |

Max efficiency (domestic model) |

No of MPPT trackers |

Warranty |

Monitoring |

Selling point |

|

SolarEdge (Israel) |

1 - 6kW |

99.2% |

1 per module |

12 years (standard) 25 years (extended) |

SolarEdge Portal |

For roofs with shading |

|

Solis (China) |

0.7 - 10kW |

98.1% |

1-3 |

5 years (standard) 10 years (extended) |

Ginlong Monitoring |

Good value |

|

Growatt (China) |

0.75 - 10kW |

98.1% |

1-3 |

5 years (standard) 10 years (extended) |

Growatt ShinePhone (app) or ShineServer (browser) |

Good value |

|

SolaX (China) |

0.7 - 8kW |

97.8% |

1-2 |

10 years (standard) 20 years (extended) |

SolaX Portal |

For DC coupled batteries |

|

SMA (Germany) |

1.5 - 10kW |

98.3% |

1-2 |

5 years (standard) 10 years (extended) |

SMA SunnyPortal |

Premium inverter from the most reputable inverter company |

|

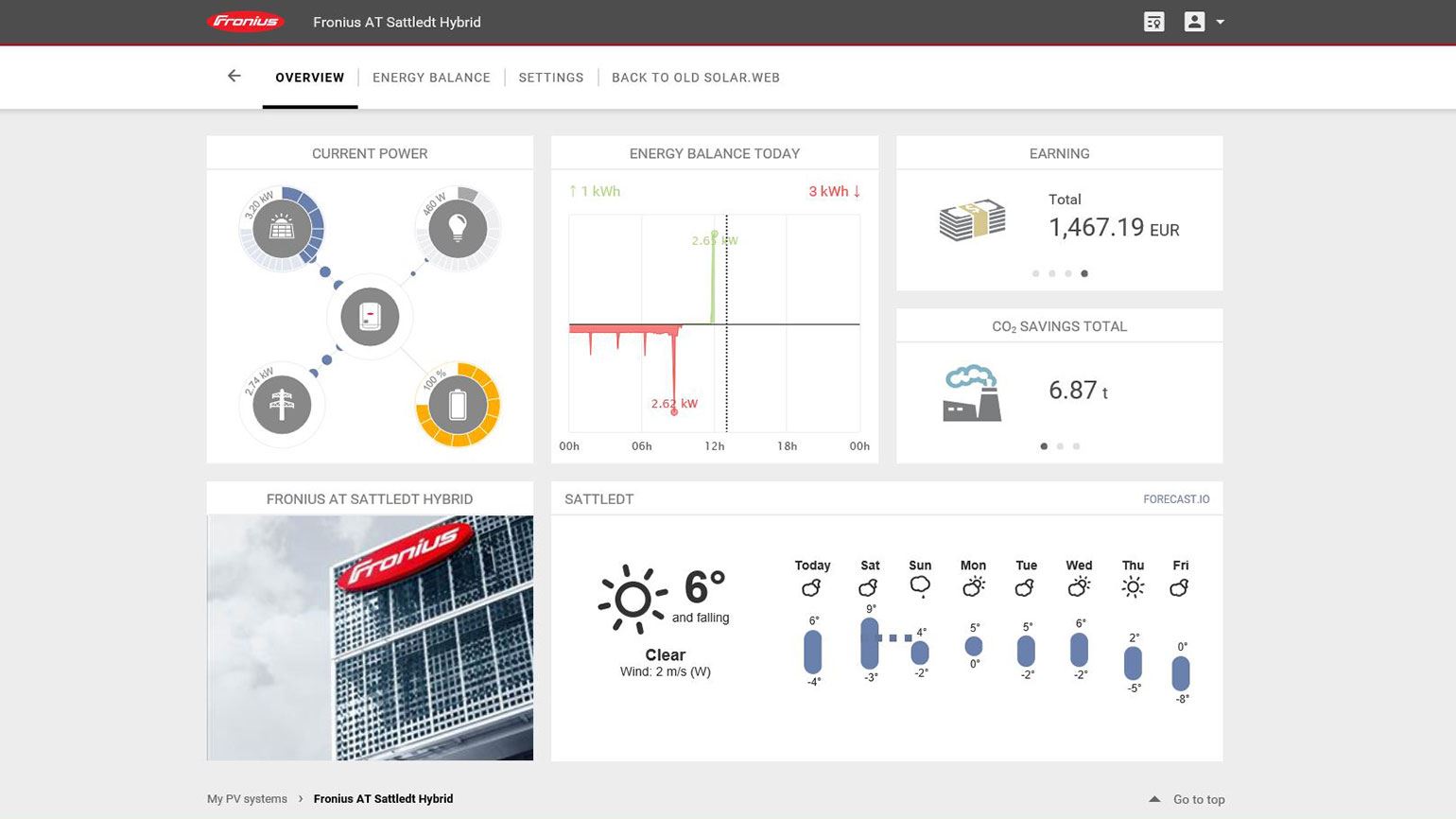

Fronius (Austria) |

1.5 - 15kW |

97.9% |

1-2 |

2 years (standard) 5 years (extended) |

Solar.web |

Large range of sizes |

|

Victron (Netherlands) |

1 - 12kW |

96.0% |

Up to 25 |

5 years (standard) 10 years (extended) |

APP and Victron Energy Portal, also local via GX Touch |

Very flexible - allows DC or AC Coupled solar, battery and generator connection. Great for 3 phase battery systems. |

|

GivEnergy (UK / China) |

3.6kW / 5.0kW only |

97.0% |

1-2 |

5 years (standard) 10 years (extended) |

App and Monitoring Portal |

Good for small solar + battery storage systems |

See our inverter overview page for more information on the different types. For small installations, the choice will be between a standard string inverter, a hybrid string inverter (allowing the efficient addition of battery storage to the system) and micro-inverters / power optimisers (increasing system output, particularly relevant for arrays subject to shading).

The best ‘standard inverters’ on the market are the Sunny Boy inverters, made by the German company SMA, as well as those made by the Austrian company Fronius. They typically come with 5 year warranties extendable to 25 years. Our standard domestic package includes a warranty extension to 10 years. However, they come at a premium so most of our customers choose the more economical to go with a Solis inverter, a cheaper but still high quality inverter.

If you read our guarantee you will see that we guarantee to investigate any fault with your system with no call out fee for five years. We do this with confidence – we really are not expecting to visit because we use high quality, well engineered, market leading inverters.

With a standard inverter, the system is optimised across a whole array of panels, and it therefore tends to be dragged down to the level of the worst performing panel. This is fine as long as all panels are generally unshaded, and in the same orientation (actually two different orientations catered to for by most inverters).

As an alternative, particularly if there will be shading on the system, you can use a micro-inverter or inverter + power optimiser system (collectively known as Module-Level Power Electronics). These optimise power output at the panel level to overcome the effects of individually lower performing modules. The best of these kinds is SolarEdge.

Solar panels are expected to last more than 25 years, and whilst they will degrade, after 25 years they are guaranteed to produce at least 80% - 90% of the ‘day one’ power output. SunPower guarantee that their panels will produce up to 92% of the ‘day one’ power output after 25 years.

Given the longevity of the panels and the system, the quality and reliability of the inverter is paramount. Choose a brand with a low failure rate and ensure that the inverter is properly specified and installed in accordance with manufacturer instructions

Inverters are usually guaranteed to last 5 or 10 years, although warranty extensions are available and the expectation is that the typical inverter should last 12-14 years. Thus an inverter change is anticipated at some point during the life of the system. However, if the inverter is well specified and properly installed, no more than one inverter change should be needed over the course of the first 25 years of the system life.

There are no officially published stats for inverter failure rate, although the expectation is that around 0.2-0.6% of inverters will fail each year, or rather, 2-6% will fail in the first 10 years.

There are a number of reasons why inverters fail:

It is important to ensure that the impact of inverter failure is minimised, firstly by checking the warranty, and secondly by ensuring that the manufacturer provides sufficient support to back-up the warranty within an acceptable time frame. We always choose manufacturers with a strong support base within the UK.

For most domestic single phase inverters, a 10 year warranty is standard. For most commercial/3 phase inverters, a 5 year warranty is standard. That said, almost every manufacturer offers warranty extensions in 5 year increments, up to 25 years.

The fine print is relevant; in particular, anything that would void the warranty needs to be avoided. The inverter will always need to be installed and maintained in accordance with the manufacturer's instructions.

A warranty is only as good as the manufacturer behind it and their responsiveness. How long do they take to respond to queries and fault notifications? Who is responsible for paying for shipping to the manufacturer?

It’s certainly easier if the manufacturer has an office in the UK.

At Spirit our domestic installations are covered by a comprehensive five year workmanship (labour and parts) warranty and we will deal with the manufacturer during this period, and through the workmanship warranty extension period should you choose to extend.

We also choose manufacturers carefully based on their product, capability and track record in product support.

Most inverters come with some degree of monitoring, usually via an online portal or an app. Some, like SolarEdge, provide panel-level monitoring, which is great for precise fault detection. As well as keeping track of the electricity you generate, it can be a good reminder to switch on devices like the washing machine or EV charger while the solar output is high.

Compare the best monitoring platforms.

Inverters are tested to various international standards. In addition, in the UK grid-tied inverters (i.e. inverters installed on systems connected to the National Grid) need to comply with the following standards:

Systems under 3.68kW: Engineering Recommendation G98 - ‘Requirements for the connection of Fully Type Tested Micro-generators (up to and including 16 A per phase) in parallel with public Low Voltage Distribution Networks on or after 27 April 2019’.

Systems over 3.68kW: Engineering Recommendation G99 - ‘Requirements for the connection of generation equipment in parallel with public distribution networks on or after 27 April 2019’.

These cover the conditions necessary for connecting a generator up to the networks of Distribution Network Operators (DNOs). They apply to both PV and energy storage systems.

For systems with an inverter under 3.68kW, we don’t need to apply for DNO permission in advance, but do it retroactively. In the rare case there’s an issue, the DNO will rectify it.

For systems with an inverter over 3.68kW, we have to apply for DNO permission (and we take care of this for you). It can take up to 3 months to be granted. If the DNO is unable to take the requested level of export power, we can either use export limitation to reduce exported power, or upgrade your supply - usually from single to 3-phase. Such an upgrade can potentially cost thousands, as you’re connecting to wherever the nearest 3-phase supply is located (digging up roads etc).

Batteries can complicate the situation further, as you need DNO permission for any with a backup supply (which most now do). Powerwall 2, for example, has a 5kW charge/discharge rate, so would need permission. Generally we recommend applying for a higher level than you might need.

PV systems are typically sized to match the demand of the relevant property, with any excess going to the grid. But sometimes this exported power can be too high for the local grid infrastructure to cope with - for example when a large commercial system doesn’t use its power on site at the weekend. To save costly network upgrades, the system can use export limitation to prevent electricity over a certain threshold from flowing into the grid.

Some inverters offer more sophisticated export limitation than others. SMA reduces the power to below the required level, while others may shut the inverter down completely. The clear advantage in the first case is that you can still claim an export tariff when you’re not consuming generated power.

Inverters are very efficient, usually around 95-98%. They will never be 100% efficient as they use some of the power from the solar array to run the conversion from DC to AC. Maximum Power Point Tracking optimises the potential output of the system at each moment and increases the inverter’s efficiency.

The datasheet of an inverter will state both its ‘peak’ efficiency, and the ‘Euro' efficiency, which is a weighted average for European climate and irradiance conditions. Euro efficiency is likely to be a percentage point or two less than the peak efficiency.

Obviously price is important and needs to be weighed up when specifying or purchasing a solar system. Products from the leading brands such as SMA and Fronius do come at a premium, as indeed does the SolarEdge system. SolarEdge will typically add around 10% to the cost of the system, but, depending on system design and complexity, it could add as much as 25% to the lifetime output. Further, the SolarEdge warranty is superior to the warranty offered by most brands: 12 years on the inverter and 25 years on the power optimisers. All of the considerations set out above need to be weighed in the balance during the system specification stage.

We can advise on the best inverter for your project when designing your system. Give us a call on 0118 951 4490 or hit the button below:

Copyright © Spirit Energy 2026 · info@spiritenergy.co.uk · 0118 951 4490

Jobs and Careers

Interested in joining the Spirit team? Email jobs@spiritenergy.co.uk

Spirit House, 25 Albury Close, Reading, RG30 1BD

(Location formerly known as 44 Portman Road, Reading, RG30 1EA)

Spirit Energy is the trading name of Spirit Solar Ltd · UK Company Number 07138647

Although care is taken to ensure that the information on our website (www.spiritenergy.co.uk) and any guides, calculators or checklists provided by us, electronically or otherwise, are accurate and up-to-date, we cannot accept any responsibility for mistakes or omissions. We enter into no express or implied conditions, warranties, terms or representations regarding the quality, accuracy or completeness of the information. We exclude to the extent lawfully permitted all liability for loss or damage, whether direct, indirect or consequential arising out of your use of our website or any guides, calculators or checklists provided by us, or from any information or omission contained in our website or any guides, calculators or checklists provided by us.